Products

- Titanium Anode

- Sodium Hypochlorite Generator

- Cathodic Protection

- Electrodeposition of Metals

- Sewage Treatment

- Electroplating

- Hydrogen Generator

- Desalination of Sea Water

- Disinfection of Swimming Pool

- Etching Solution to Recover Copper

- Titanium Bicycle Parts

- Titanium Handlebar

- Titanium Frame

- Titanium Fork

- Titanium Stem

- Titanium Seatpost

- Titanium Pedal Spindle

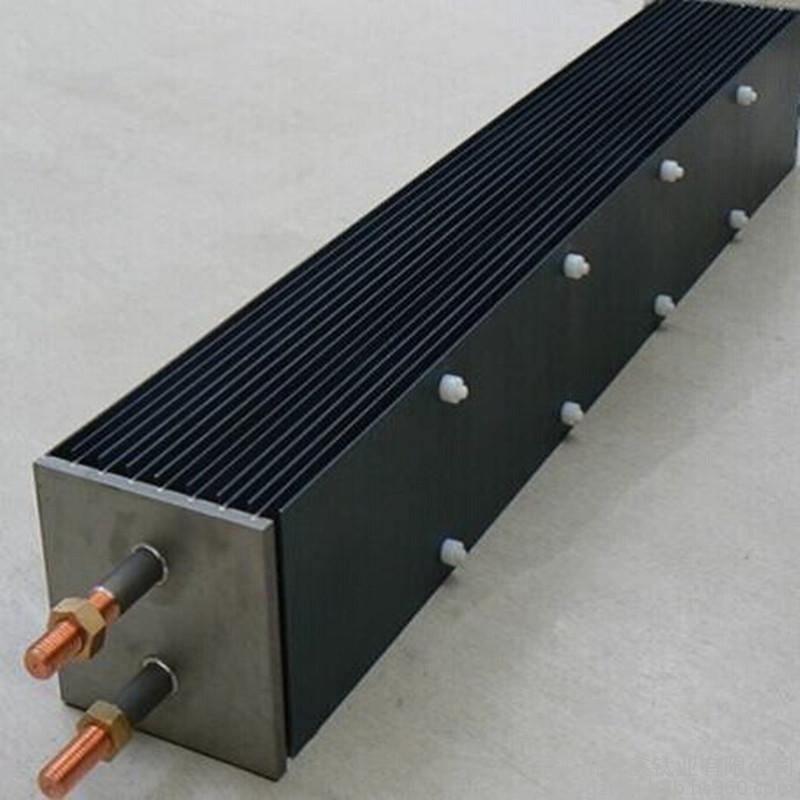

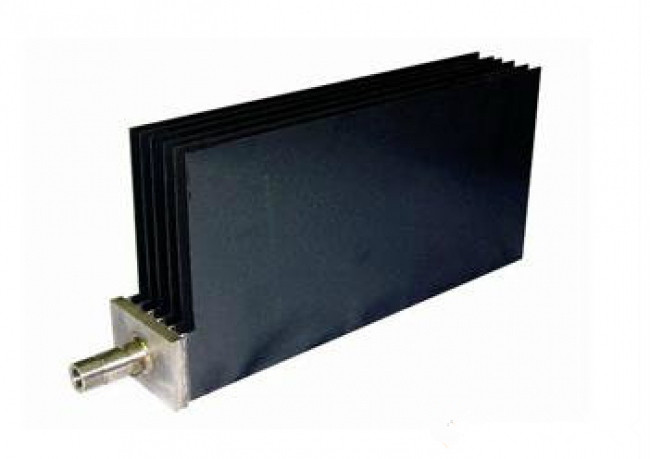

MMO titanium anode for Chlorinator

Product description

The cell of a salt chlorinator is the part that actually converts the salt (NaCl) into chlorine and consists of a plastic housing and electrodes. The electrodes are usually made of titanium, a highly corrosion-resistant material, and the anode is usually coated with ruthenium or iridium oxide. The composition of this coating plays an important role in both the efficiency of the cell's chlorine production and its expected lifetime.

Specification: customized according to customer drawings.

1. Coating Metal: Titanium-based ruthenium-iridium coated electrode.

2. Current Density: 2000A/m2.

3. Temperature: <50℃

4. Salt solution concentration: 3-5%.

5. Coating Thickness: 6-10 micron.(10g/m2)

Application

1. Chlorination systems for swimming pools.

2. Swimming pool chlorine generators.

3. Swimming pool salt generators.

4. Brine chlorine generators.

5. Salt cell generators.

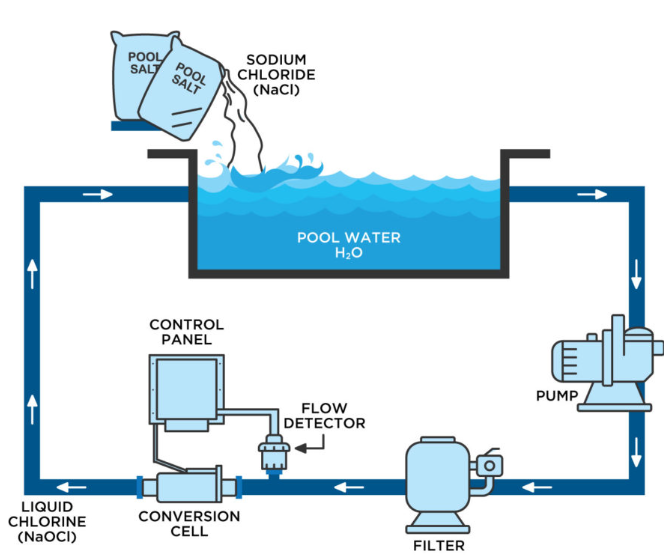

Working Principle

(1) When microorganisms come into contact with the electrode, the additional potential at the contact interface, or a potential gradient of 106 V/cm) damages the cell membrane.

(2) Electrochemical effects occur within the microorganism when it comes into contact with the electrode.

(3) Secondary sterilisation of active substances produced by electrolysis.

(4) Variation of the pH value with electrolysis.

(5) Sterilisation by warming through the generation of Joule heat at the electrode interface.

(6) Sterilization of microorganisms by electric current.

(7) Sterilisation can be carried out under high frequency conditions according to the principle of inductive diffusion.

Most electrolytic sterilisation devices are based on electrolysis of a solution containing chloride ions to produce NaClO at the anode for sterilisation.

Feature

1. Self-cleaning electrolytic cell, (Auto SC) unit

2. Polarity reversing electrodes, low maintenance

3. Prevents algae growth

5. Scale inhibiting cathodes

6. Large surface area cell plates for high chlorine production rates

7.Separately replaceable anode and cathode units avoid replacement costs

1. 6+ years service life in chlorine production industry.

2. 2 years warranty.

3.Factory direct price.

4. 20 years titanium anode production experience.

5. Japanese advanced technology.

6.Heraeus imports precious metals

7. The lastest sintering process.

8. Support samples.

Proper maintenance of salt chlorinators

—To maximise the life of your salt chlorinator, consider the following tips.

—Use with reverse polarity electrodes to greatly reduce scale build-up on the cell and extend the life of the chlorinator.

—Maintain a consistent salt level (typically 2700-3900 ppm)

—Clean the chlorinator chamber at least once a quarter or as required

—Avoid cleaning the chlorinator cell too often

—Turn off the pool unit during thunderstorms to avoid damaging power surges

—Keep calcium levels as low as possible and still meet the guidelines set by the pool equipment manufacturer